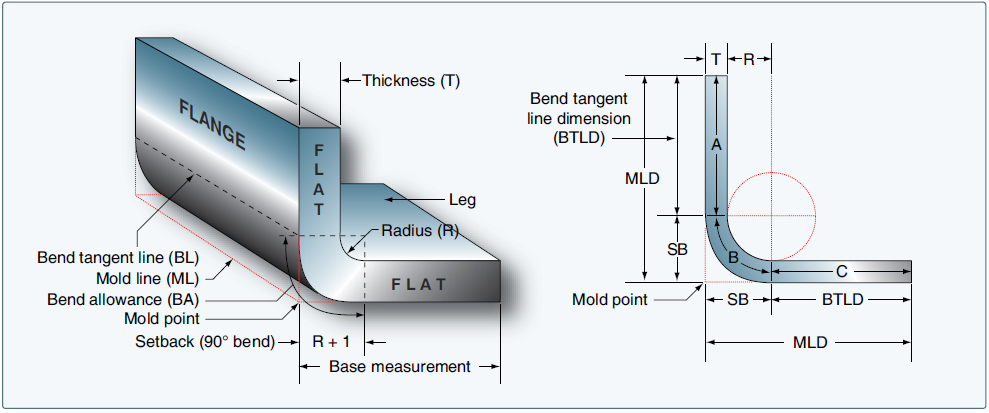

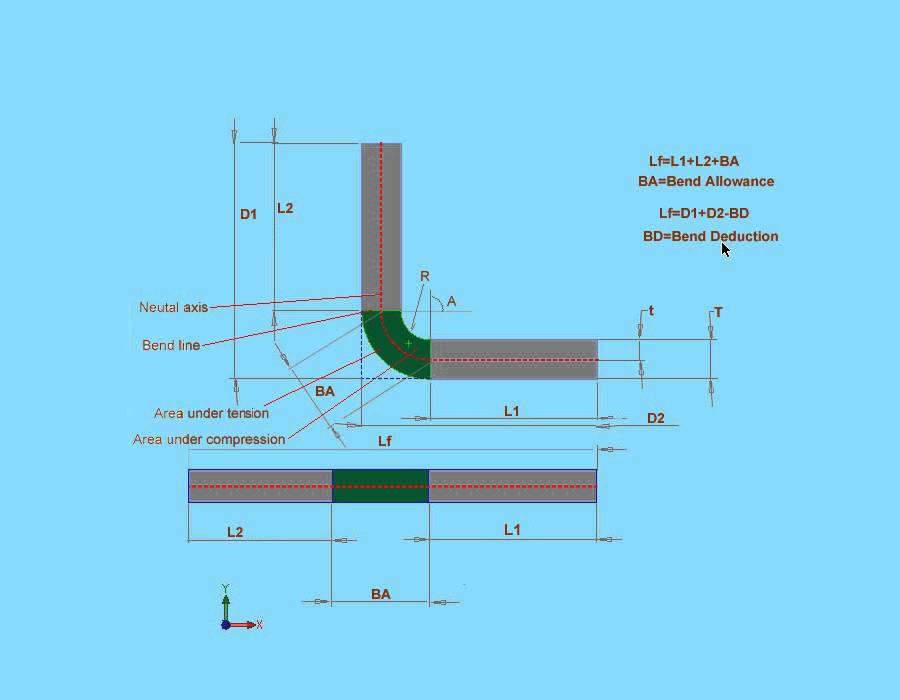

The bend allowance is defined as the material you will add to the actual leg lengths of the part in order to develop a flat pattern.

Calculating flat pattern length sheet metal.

Here are the steps to be followed to calculate sheet metal flat length.

Use k factor calculator to calculate k factor values.

Likewise when you are trying to develop a flat pattern you will have to make a deduction from your desired part size to get the correct flat size.

Bend allowance ba the amount of added to the sum of the two leg lengths to obtain the flat pattern length.

As this happens you gain a small amount of total length in your part.

Sheet metal flat length can be calculated in the following three simple steps.

Enter k factor values.

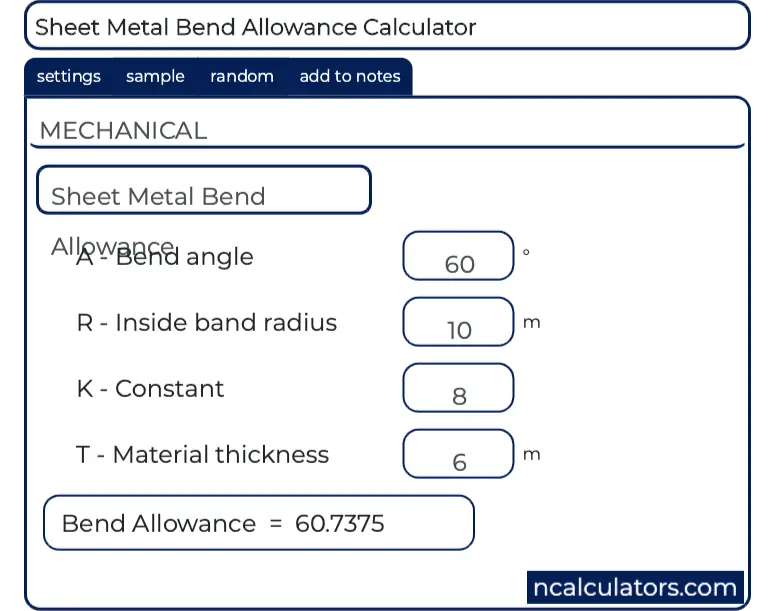

Calculate the value bend allowance for required sheet metal bend by using below formula.

60 90 and 120 and we will calculate k factor bend allowance and bend deduction for them.

When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched.

With this free online tool we quickly get the sheet metal bend deduction and therefore the sheet metal blank initial flat length from the finished part measurements.

Bend allowance ba π 180 r k t a.

The curved steel cone calculator from chicago metal rolled products makes it easy to find the precise curved steel cone dimensions you need.

Consider a sheet with a 20 mm thickness and a length of 300 mm as shown in figure 1.

Sheet metal cone calculator.

I ve worked with cmrp for over 16 years and can rely on them for any size job and in any time frame.

Bend deduction bd the amount removed from the sum of the two flange lengths to obtain a flat pattern.

Cmrp delivers every time.

It allows you to determine either the size of raw material needed or the number of gore sections to fit on your available material.

View the cone instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections.

Likewise when you are trying to develop a flat pattern you will have to make a deduction from your desired part size to get the correct flat size.

Time and material is wasted on various tests before getting a reliable value.

If the value of sheet metal k factor and bending flange length is known.

Kindly let me know if any.

Value of bend deduction and flat pattern are shown in result section.

Enter flange length internal radius and thickness values.

As this happens you gain a small amount of total length in your part.

The stated parameters smt flat pattern length and smt flat pattern width are getting created for the parts with bends.

Flat pattern inside radius.

We are going to review three bending scenarios with three different bending angles.